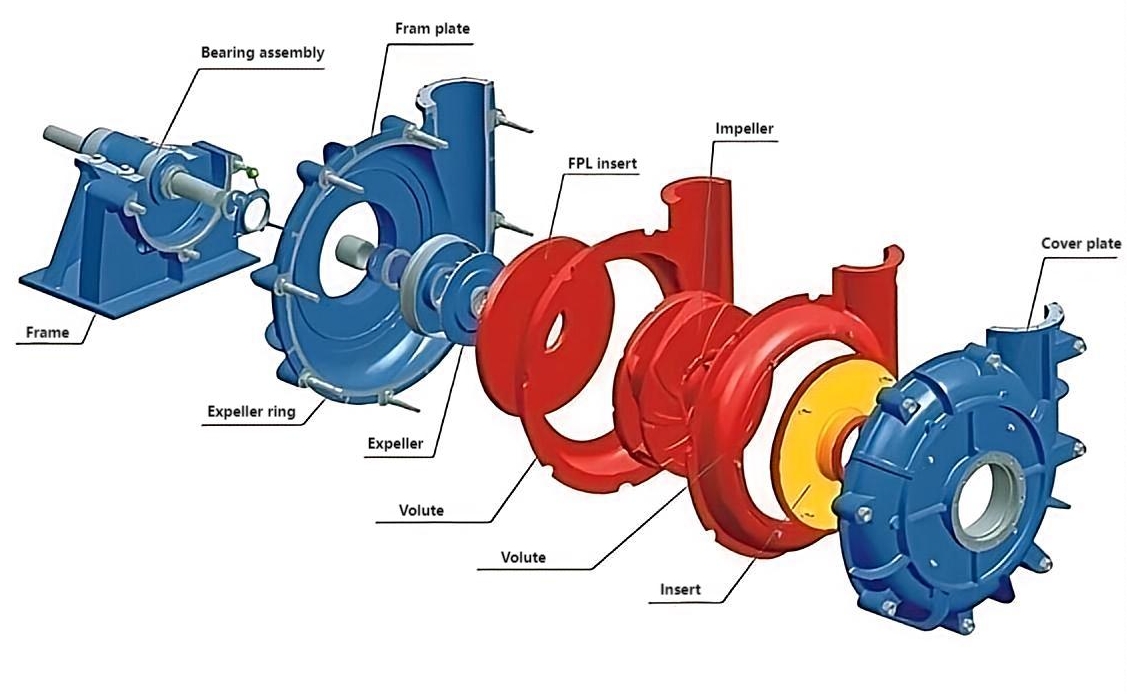

Slurry pump refers to a machine that increases the energy of solid and liquid mixed medium by means of centrifugal force(rotationof the impeller of the pump),and converts the electric energy into the kinetic energy and potential energy of the medium.Mainly applicable to mining,power plant,dredging,metallurgy, chemical,building materials and petroleum and other industries.

PRODUCT DESCRIPTION

PRODUCT DESCRIPTIONSlurry Pump

Slurry pump refers to a machine that increases the energy of solid and liquid mixed medium by means of centrifugal force(rotationof the impeller of the pump),and converts the electric energy into the kinetic energy and potential energy of the medium.Mainly applicable to mining,power plant,dredging,metallurgy, chemical,building materials and petroleum and other industries.

Adavantage

◊ Widely used in industries of mining, metallurgy, electric power, coal, chemicals, building etc, transporting abrasive or corrosive slurry.

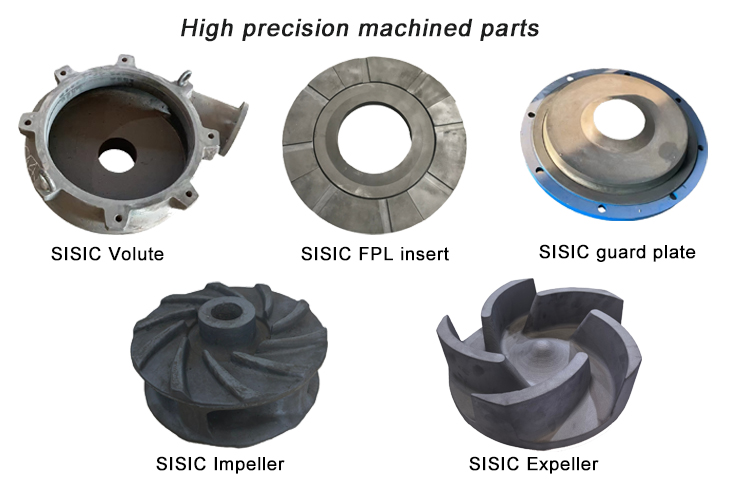

◊ Interchangeable high wear resistant metal or SISIC(silicon carbide reaction-sintered)liner, so as the impeller. ( about 5 times more than that of rubber )

◊ Excellent wear life, Easy maintenance.

◊ Best total operating cost.

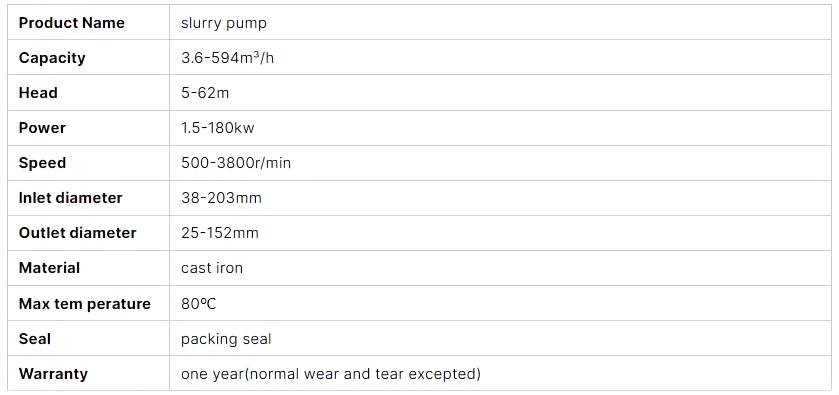

Product Parameters

We use new materials to react sintered silicon carbide(SISIC) slurry pump processing parts replaced by traditional rubber materials, the use of silicon carbide high temperature resistance, high wear resistance, corrosion resistance, thermal shock resistance and other characteristics, so that the service life of the parts far beyond the rubber material.

Silicon Carbide(SISIC)Product Parameters

| Item | Unit | Data |

| Temperature of application | °C | ≤1380 |

| Density | g/cm³ | ﹥3.02 |

| Open porosity | % | 0 |

| Bending strength | Mpa | 250(20°C ) |

| Mpa | 280(1200°C ) | |

| Modulus of elasticity | Gpa | 330(20°C ) |

| Gpa | 300(1200°C ) | |

| Thermal conductivity | W/m.k | 45(1200°C) |

| Coefficient of thermal expansion | K∧-1×10∧-6 | 4.5 |

| Rigidity | 9.6 | |

| Acid-proof alkaline | 45(1200°C) |

COMPANY PROFIE

COMPANY PROFIEWeifang Xinda Fine Ceramics Co.,LTD.was established in 2014.The company serves electric power,iron and steel,mining,metallurgy,chemical industry,coal,wet flue gas desulfurization,industrial kilns and other special industries.

The company has introduced German advanced technology and is in a leading position.The main products are Silicon carbide cyclone liner,Silicon carbide burner nozzle,Silicon carbide frame energy-saving kiln furniture,silicon carbide grinding barrel,silicon carbide radiant tube,silicon carbide slurry pump impeller,silicon carbide desulfurization nozzle,silicon carbide beam,silicon carbide roller,silicon carbide plate,silicon carbide wear resistant,silicon carbide crucible,silicon carbide heat-exchanger tube,silicon carbide wafer boat and other products.The hardness of the product is second only to diamond,and it has the main characteristics of high strength,high hardness,high wear resistance,corrosion resistance,high temperature oxidation resistance,cold and heat resistance,high thermal efficiency.It is one of the products with the best performance and the highest cost performance in the field of special industrial ceramics.

Our company's reaction sintered silicon carbide products have reached the European industry standards,quality reached the world advanced level,the products have been exported to Russia,Korea,Japan, Vietnam,the United States,Germany,Italy, South Africa, Australia, Malaysia,Thailand, the United Arab Emirates and other countries and regions. With the tenet of quality first,customer first,we sincerely welcome friends from all over the world to discuss cooperation and create a better future together.

Exhibition

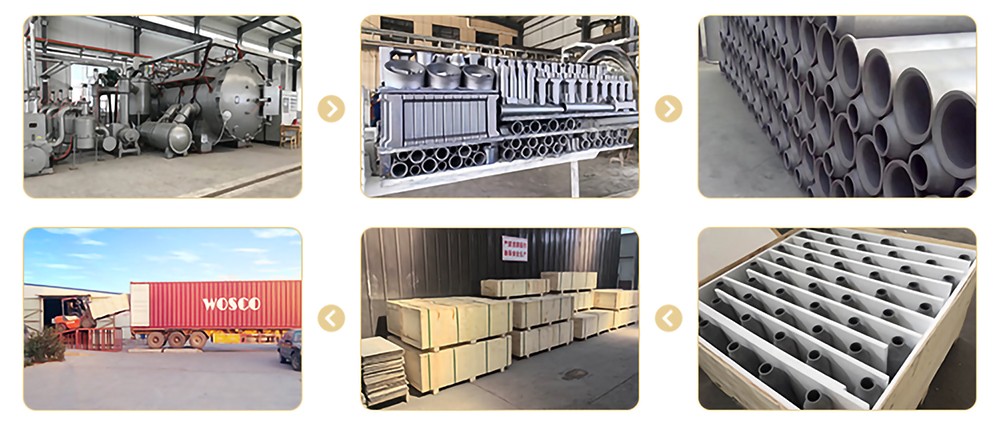

PRODUCTION LINE

PRODUCTION LINE

RECOMMEND PRODUCTS

RECOMMEND PRODUCTS