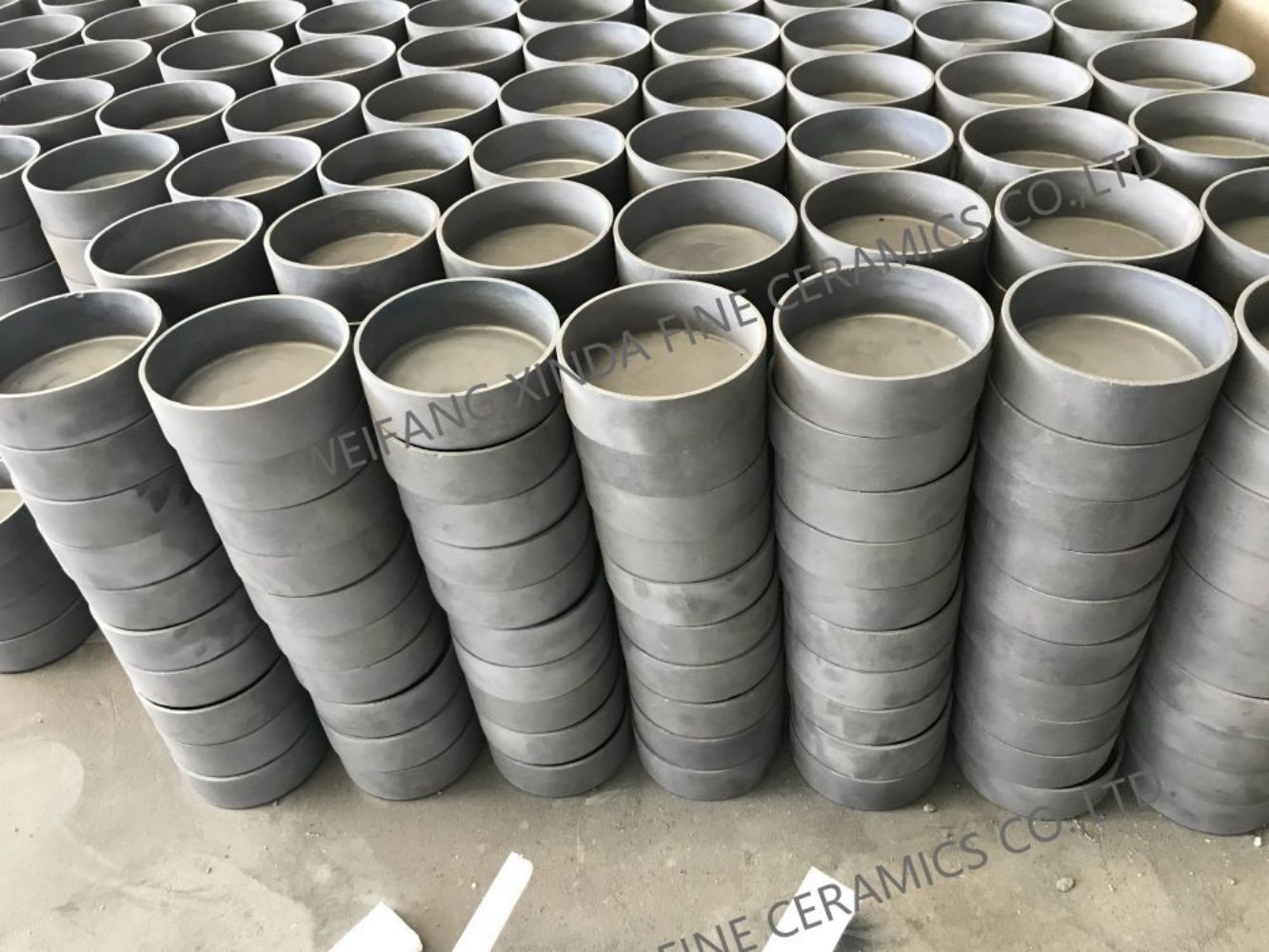

Silicon carbide crucible&sagger has the characteristics of large volume density, high temperature resistance, fast heat conductivity, acid and alkali corrosion resistance, high temperature strength, good stability, high oxidation resistance, long term repeated use of no deformation and no slags, the service life is several times or even tens of times of the general material,can be customized according to the user's different use environment of various specifications.It has been widely used in non-ferrous metal smelting, sintering of various ceramic raw materials, high-grade porcelain, sintering of lithium batteries and other electronic materials, and other high-temperature sintering industries such as rare metal smelting.

Silicon carbide crucible&sagger has the characteristics of large volume density, high temperature resistance, fast heat conductivity, acid and alkali corrosion resistance, high temperature strength, good stability, high oxidation resistance, long term repeated use of no deformation and no slags, the service life is several times or even tens of times of the general material,can be customized according to the user's different use environment of various specifications.It has been widely used in non-ferrous metal smelting, sintering of various ceramic raw materials, high-grade porcelain, sintering of lithium batteries and other electronic materials, and other high-temperature sintering industries such as rare metal smelting.

Feature

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 6 times more than that of alumina ceramic )

| Item | Unit | Data |

| Temperature of application | °C | ≤1380 |

| Density | g/cm³ | ﹥3.02 |

| Open porosity | % | 0 |

| Bending strength | Mpa | 250(20°C ) |

| Mpa | 280(1200°C ) | |

| Modulus of elasticity | Gpa | 330(20°C ) |

| Gpa | 300(1200°C ) | |

| Thermal conductivity | W/m.k | 45(1200°C) |

| Coefficient of thermal expansion | K∧-1×10∧-6 | 4.5 |

| Rigidity | 9.6 | |

| Acid-proof alkaline | 45(1200°C) |

Weifang Xinda Fine Ceramics Co.,LTD.was established in 2014.The company serves electric power,iron and steel,mining,metallurgy,chemical industry,coal,wet flue gas desulfurization,industrial kilns and other special industries.

The company has introduced German advanced technology and is in a leading position.The main products are Silicon carbide cyclone liner,Silicon carbide burner nozzle,Silicon carbide frame energy-saving kiln furniture,Silicon carbide grinding barrel,Silicon carbide radiant tube,Silicon carbide slurry pump impeller,Sic Desulfurization nozzle,Silicon carbide beam,Silicon carbide roller,Silicon carbide plate,Silicon carbide wear resistant,silicon carbide crucible,Silicon carbide heat-exchanger tube,Silicon carbide wafer boat and other products.The hardness of the product is second only to diamond,and it has the main characteristics of high strength,high hardness,high wear resistance,corrosion resistance,high temperature oxidation resistance,cold and heat resistance,high thermal efficiency.It is one of the products with the best performance and the highest cost performance in the field of special industrial ceramics.

Our company's reaction sintered silicon carbide products have reached the European industry standards,quality reached the world advanced level,the products have been exported to Russia,Korea,Japan, Vietnam,the United States,Germany,Italy, South Africa, Australia, Malaysia,Thailand, the United Arab Emirates and other countries and regions. With the tenet of quality first,customer first,we sincerely welcome friends from all over the world to discuss cooperation and create a better future together.